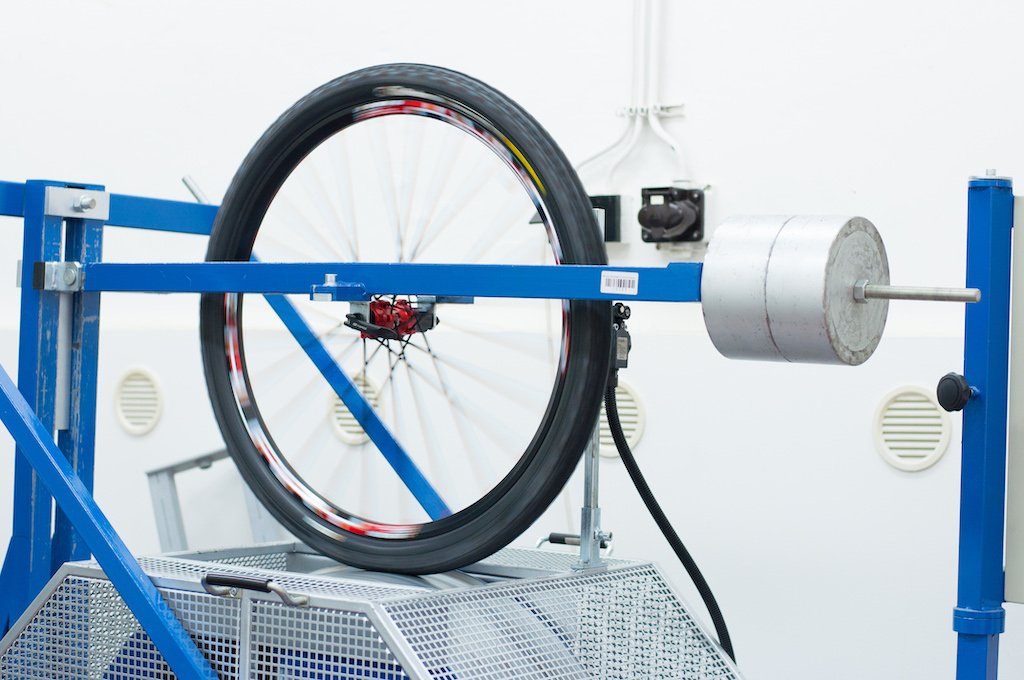

A bicycle is quite a complex product, and numerous tests have to be done to verify its full functionality, robustness and durability. Your bicycle should meet all the requirements of the applicable standards that we mention here, as they are based on the requirements of the applicable standards. It is the responsibility of the manufacturers to demonstrate conformity of their products to the applicable standards and to declare that the products meet all the requirements laid down.

Generally, the manufacturers can demonstrate conformity of their products in two ways:

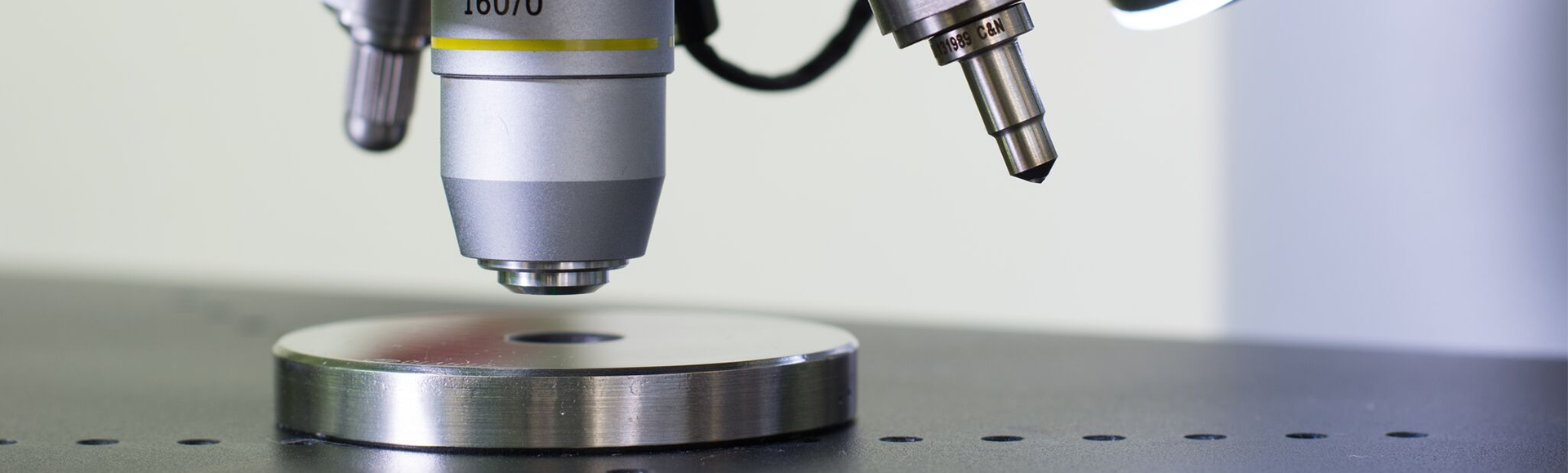

The manufacturer has its own, in-house test station and verifies all the parameters in there.

The manufacturer has the parameters verified by one of the testing laboratories that are competent to perform the required tests.

E-bikes (including the abovementioned):

Section Manager of Machinery, work and leisure equipment

storek@szutest.cz

+420 483 348 279

+420 720 869 722

1.

Inquiry

If you are interested in any of our services, please contact us.

2.

Specification

Our experts will contact you soon and specify the details of your inquiry.

3.

Offer

After clarifying the details we will prepare a final offer for you.

4.

Order

You will then fill in a binding order.

5.

realization

After signing the contract, we will start to execute your order.