The statistical method is used for the product class where there is a clear relationship between the probability of occurrence of the failure and the lifetime of the equipment.

Based on the manufacturer's provided statistical data, the probability of occurrence of a dangerous undiagnosable failure is determined, which becomes then the basic data for determining the appropriate SIL level.

The calculation is based on the statistical data provided by the manufacturer (customer), which is a statistical sample. This sample must include the identification of the individual products in the sample, each product record of the operation (at the start and end of the product tracking), a record of the occurrence of failures in the observed time interval, and a record of the type of malfunction that has occurred and how to remove it.

Incomplete or inaccurate data in the documents for calculation, insufficient sample size (product of the number of monitored products and number of working hours) for the required SIL level.

The analytical method is used for larger complex systems composed of modules (parts) where the required statistical values are defined by the manufacturer.

Based on the manufacturer's provided list of components, technical data on components and equipment structure and software life cycles, the probability of a dangerous undiagnosable loop failure is calculated by using the formulas and tables in ČSN EN 61508-6 ed.2 (or ČSN EN ISO 13849-1:2008), which then becomes the basic data for determining the appropriate SIL level.

Determination of the SIL level is made by calculating the technical data on individual parts of the equipment and the descriptions and drawings of the system configuration. If security programmable parts (control computers) are used, the software is evaluated for the logical accuracy of the programmed functions. The suitability of the security software and the correctness of the programmed logic functions are assessed by methods given in ČSN EN 61508-3 ed.2 (possibly in a simplified form in ČSN EN ISO 13849-1).

Incomplete or inaccurate data in the documentation for calculation, insufficient software life cycle documentation, use of components with undefined security features in security loops.

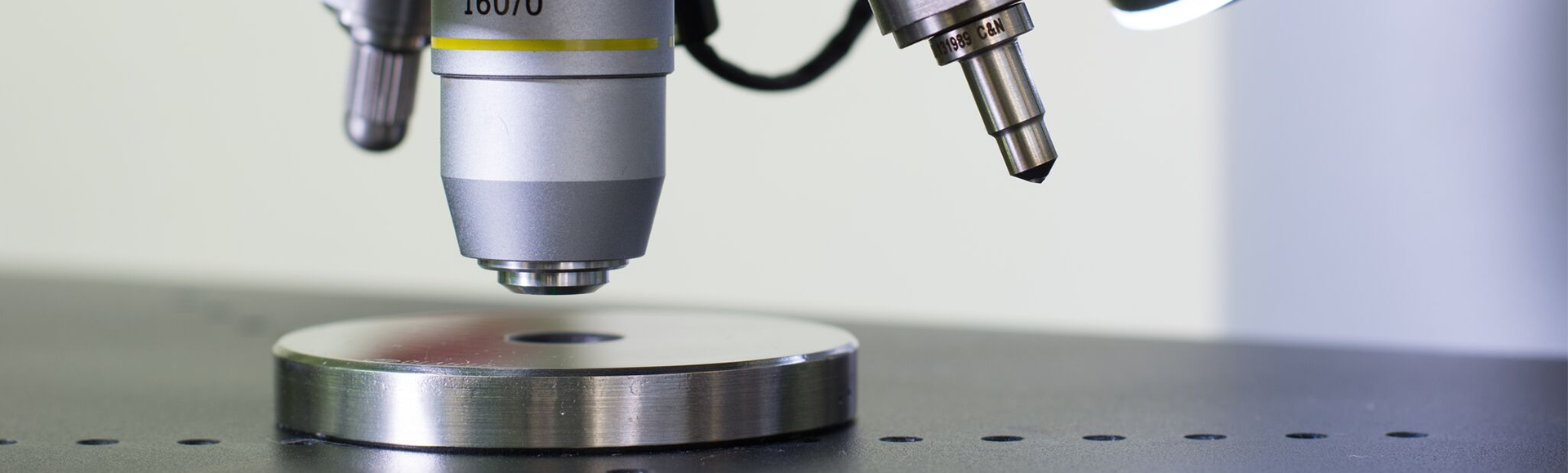

Medical Devices and Laboratory Equipment Specialist

bauer@szutest.cz

+420 541 120 621

+420 606 628 340

1.

Inquiry

If you are interested in any of our services, please contact us.

2.

Specification

Our experts will contact you soon and specify the details of your inquiry.

3.

Offer

After clarifying the details we will prepare a final offer for you.

4.

Order

You will then fill in a binding order.

5.

realization

After signing the contract, we will start to execute your order.