Our colleague began working in testing an impressive fifty years ago and continues to do so today. Read his fascinating story, interwoven with adventurous work missions to exotic parts of the world.

During my three years of university studies, I focused on new teaching methods and had access to a well-equipped darkroom for color photography at the Department of Mechanization, which was exceptional in 1974.

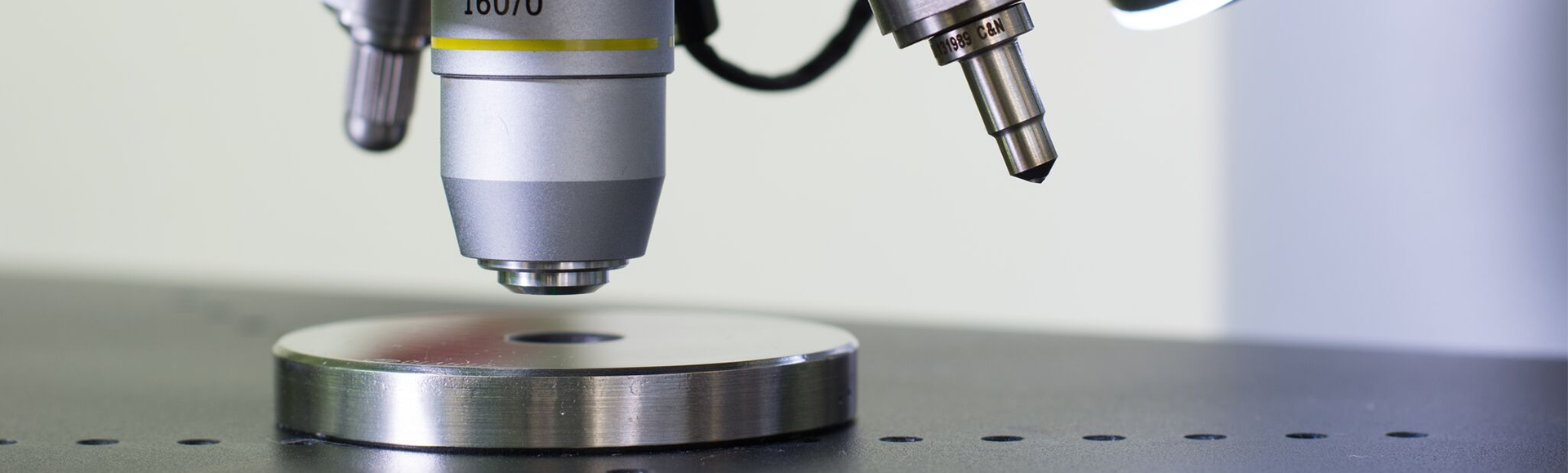

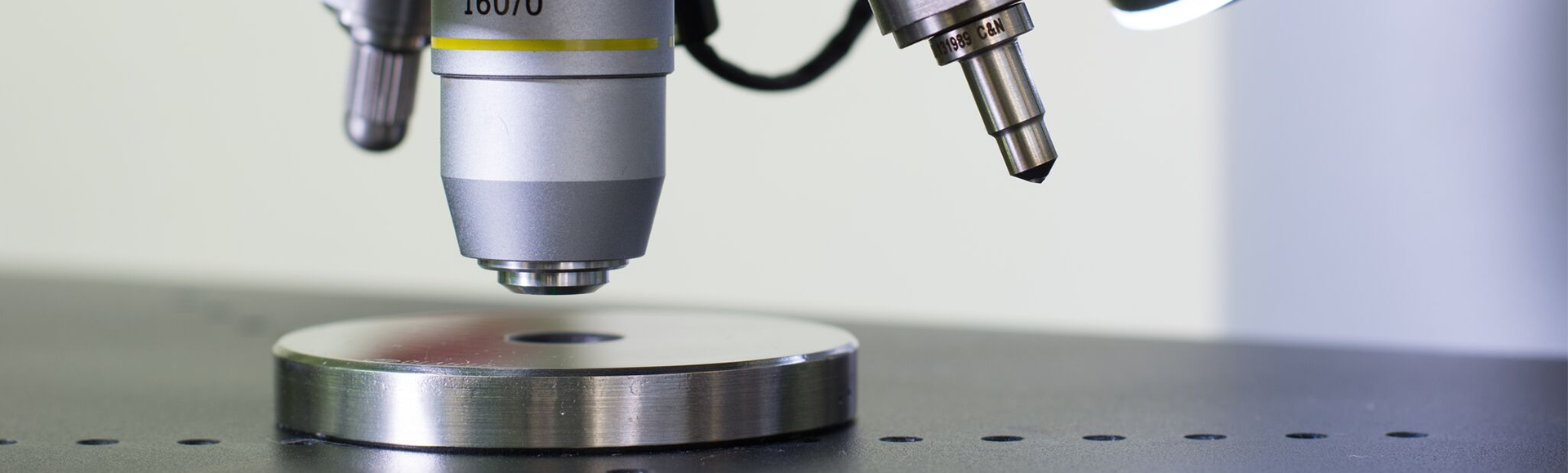

I joined SZÚ after graduating and, logically, started as a technician in the precision mechanics and optics testing laboratory. The testing laboratory expanded, reorganizations took place, and new fields were added, such as control technology, health technology, automation components, etc.

My work at SZÚ during those years was interwoven with interesting foreign missions to parts of the world that were exotic to us at the time.

In 1984, ÚNMZ, in cooperation with the foreign trade company Polytechna, won a contract with the United Nations Industrial Development Organization (UNIDO) to establish the Ethiopian Standards Institution in Addis Ababa. I was successful in the selection process and went there for eight months.

It was an invaluable experience for me – constant communication in English, having to take care of myself, including cooking, getting to grips with the UN work system, etc. It wasn't easy there at the time, as Ethiopia was at war with Eritrea and famine was raging in the country. That's probably why no one from the West wanted to go there, so technicians from the East were given the opportunity.

However, I took advantage of this opportunity and registered directly in the UNIDO database of external collaborators, because Polytechna, as an intermediary, also took a substantial part of my salary.

After my return, I became the head of the SZÚ control department (which checked the quality of protocols and records of measurements and tests). I remember that at that time, SZÚ had around 300 employees.

In 1989, based on an international UNIDO tender, I left for seven months, this time as the head of a group of experts tasked with establishing the Yemen Standards Institution in Sana'a. Now there is fighting there, but back then it was great; on weekends we would hitchhike around to explore the beauty of Yemen.

After returning from Yemen in the spring of 1990, the management of SZÚ indicated to me that, as the head of the testing laboratory, I would no longer be able to go on such long missions abroad. Despite this criticism, I continued my work and, with my decent knowledge of English, I became the author of the first translations of the ISO 9000 and EN 17000 series of standards into Czech.

I must have had a good rating in the UN system, because in the fall of 1990, I was selected for the position of UNIDO project director for the establishment of the Standards Organisation of Nigeria (SON). I asked the management for long-term unpaid leave and resigned from my position as head of the testing laboratory (at that time, I think the largest in the SZÚ). Originally, it was for one year with the possibility of extension to three years. It was a bit of a risk, but I went for it. In the end, I stayed there for seven years, and thanks to that, my sons were able to attend secondary school and university in England.

In my free time, I always tried to get to know the country I was in. In Ethiopia, I started running (marathon runner Abebe Bikila was my role model, and I visited his grave). In Yemen, there was an active Czech community (alcohol could only be drunk at the embassy), and because Muslims don't work on Saturdays and have Ramadan, there were plenty of opportunities to travel.

In Nigeria, I built (from construction to equipping the testing laboratories to their full operation) a construction and electrical engineering testing laboratory in Enugu, a leather and textile testing laboratory in Kaduna, and in Lagos, where I lived, there was the SON headquarters, and we established a standardization institute there, including a computing center, processing and publishing texts on computers. After Nigeria, I traveled about 200,000 km. I have enough experiences to fill a book.

After returning from Nigeria in January 1998, I also returned to SZÚ. To the credit of SZÚ's management, I was given a position as a development officer for SZÚ. The main task was to raise SZÚ to an international level.

However, in September 1998, a selection procedure was announced for the position of director of the Technical and Testing Institute for Construction in Prague (TZUS) with ten branches within the Czech Republic. I passed the relevant interviews and tests (I particularly enjoyed the English test) and was selected by the Ministry of Industry and Trade.

However, thanks to its previous management, TZUS was in a rather poor state, with invalid accreditation certificates, so my first trip was to the Czech Accreditation Institute (ČIA), where we worked together to ensure the institute's operability. Over time, the situation consolidated, TZUS expanded into new fields (acoustics, crash tests of guardrails, toys and furniture, fire tests, etc.) and became a member of a number of international associations of construction testing laboratories.

As chairman of Eurolab cz, I represented the Czech Republic in Eurolab aisbl (a European organization based in Brussels). I was elected chairman of Eurolab aisbl for four years with the task of coordinating testing within the EU, cooperating with European accreditation and the European Commission, and promoting European interests at the global level (ISO, ISO CASCO, ILAC, etc.).

During my 15 years at TZUS, I participated in EU accession negotiations with an emphasis on construction, mainly the transposition of the Construction Products Directive into national legislation.

At a certain stage, the issue of privatizing state testing laboratories arose, which was something I could not agree with from a professional point of view (arguments and specific analyses of state testing solutions in EU countries and other states were not taken into account). After privatization was halted (2012), the Ministry of Industry and Trade announced a tender for the director of state testing laboratories, in which I was unsuccessful.

I continued at TZUS as director for international affairs, but at the same time I responded to a tender announced by the EC for an EC consultant for construction. In the meantime, the management of SZÚ allowed me to work on developing international contacts, thanks for the support. I was successful in the European tender and since January 2014 I have been working as a consultant for European Assessment Documents (EAD), which I really enjoy. Practically every week, I have a different construction product in my EAD office at home, which I have to comment on from a technical, formal, legal, and linguistic point of view, so I have to keep learning.

My first project was an Anaret magnifying lens from Meopta Přerov, which was one of my most important customers. We also conducted testing in their company testing laboratory.

There are many testing experiences, but in relation to Meopta, imagine a young engineer thinking in millimeters arriving at the best-equipped optical testing laboratory in the Czech Republic, where they work in nanometers, and mostly in the dark.

I haven't finished yet; I'm still working in testing. EAD is a harmonized technical specification valid within the EU, and in essence it is a uniform methodology for testing and assessing a specific innovative product (for which there is no harmonized standard yet). Assessment according to EAD is necessary for CE marking of a product. So, I have not left the field throughout my professional career, and I have a contract with the EC until 2029.

I appreciate the wide range of fields my work covers. I also enjoy the fact that I am constantly learning new things, which keeps my mind fresh.

Those who remember will recall that I am also a musician – I still play the harmonica, mainly folk music at events such as the folklore festival in Bosonohy. I have well-equipped workshops for metal and wood, and I even dare to tackle furniture made from exotic solid wood (everything has to be right first time).

After spending all day looking at six monitors in the office, manual work is the perfect way to relax. I really enjoy photography. I exercise every morning and go running or swimming in the evening.

I live for my four granddaughters and one grandson, whom I support in their studies abroad by providing them with high-quality musical instruments (they all play something and are very good at it).

In the spring of 2025, I was newly registered in the UN system as an international expert in monitoring and evaluating infrastructure projects in the field of quality (testing, certification, accreditation).

Thank you for the interview! The SZÚ team